Better Touch Better Business

Contact Sales at Proway safe suppliers.

Fireproof safes are crucial safety devices designed to protect important documents, valuables, and cherished memories from the devastating effects of a fire. Their ability to provide effective fire protection is attributed to their special design and material selection.

Below are key factors explaining how fireproof safes achieve their fire resistance:

Material Selection:

Asbestos:

Characteristics: Asbestos is a natural mineral with excellent fire resistance and high temperature resistance.

Application: Due to its fire resistance and high temperature resistance, asbestos was widely used in building materials such as roof tiles, insulation boards, and soundproofing boards.

Safety Concerns: Although asbestos has outstanding fire resistance, it has been proven to be harmful to human health, as prolonged exposure to asbestos fibers can lead to serious health issues, including lung diseases and cancer. Therefore, many countries have banned or restricted the use of asbestos.

Gypsum Board:

Characteristics: Gypsum board is a lightweight, fire-resistant building material made of gypsum and reinforced fibers.

Application: Gypsum board is commonly used for the construction of interior walls and ceilings, and its fire resistance makes it a common fire barrier material. In the event of a fire, gypsum board can prevent the spread of fire and provide additional protection time.

Advantages: Gypsum board is relatively easy to process and install, and it has a lower cost, making it a widely used fireproof material.

Cement:

Characteristics: Cement is a building material made of cement, aggregate, sand, and water, with good fire resistance.

Application: Cement is commonly used for the construction of building structures such as walls, floors, and ceilings. In the event of a fire, cement has excellent fire resistance, effectively preventing the spread of fire and providing time for evacuation.

Advantages: Cement has high fire resistance and durability, and it is relatively easy to obtain and process, making it widely used in fire protection projects in the construction industry.

Performance of Fire-Resistant Materials:

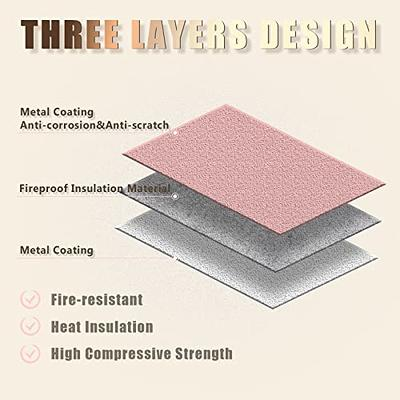

fire-resistant materials (Steel): Possesses excellent tensile strength and hardness, resisting deformation at high temperatures.

Concrete: Known for its insulating properties, it can slow down the spread of flames.

Ceramic fiber: Exhibits outstanding resistance to high temperatures, effectively isolating heat.

Structural Design:

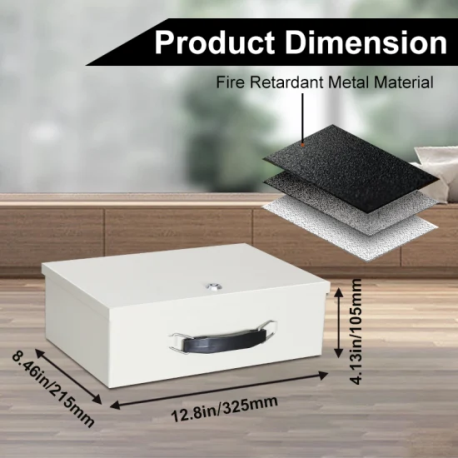

The structural design of fireproof safes considers fire resistance. Some designs incorporate a composite structure, such as a combination of metal and concrete, to enhance overall fire resistance. Structural design also includes factors like heat insulation and fire-resistant sealing materials, ensuring a relatively stable internal environment.

Heat Insulation Performance:

Fireproof safes consider heat insulation performance, a key factor in their successful fire resistance. High temperatures pose a significant threat during a fire, and effective heat insulation slows down heat transfer, extending the safety time for the contents inside.

Fire-Resistant Sealing Materials:

Fireproof safes are often equipped with fire-resistant sealing materials, such as fireproof gaskets. These materials serve as seals during a fire, preventing smoke and moisture from penetrating the interior and helping maintain a relatively stable internal environment.

Professional Testing and Certification:

High-quality fireproof safes typic.

The fireproof strip of a fireproof safe typically refers to the sealing or insulating strip inside the safe, which is used to prevent the entry of hot air, smoke, and flames during a fire. These fireproof strips are a crucial component in the design of a fireproof safe, helping to maintain a relatively low temperature inside the safe and providing better fire protection.

The functions of the fireproof strip in a fireproof safe generally include:

Sealing Function: The fireproof strip inside the safe provides effective sealing, preventing external air, smoke, and flames from penetrating into the safe. This helps maintain a relatively isolated environment inside the safe.

Insulating Function: Fireproof strips typically use heat-resistant materials, such as special fireproof rubber or fire-resistant materials, to slow down the transfer of heat and prevent the internal temperature from rising too quickly.

Fireproof Layer Isolation: Some fireproof safes have fireproof strips designed to form a fireproof layer during a fire, preventing direct contact with heat and flames. This helps delay the rise of internal temperature, providing extended fire protection.

The fire resistance level of fire safes is typically determined through a series of tests and certifications that simulate real fire scenarios, assessing the safe's performance under conditions of high temperature, flames, and smoke. The fire resistance level indicates the extent to which the safe can withstand the intrusion of fire and protect the contents inside.

Here are some common fire resistance levels for fire safes:

UL Standard:

Class 350: Indicates that, during a fire, the internal temperature does not exceed 350 degrees Celsius (662 degrees Fahrenheit) for a specified duration. This level is often used for document safes designed to protect paper documents, videotapes, and similar items.

EN 1047 Standard:

S60P: Signifies that the safe can resist high temperatures up to 900 degrees Celsius (1652 degrees Fahrenheit) during a fire.

S120P: Indicates the safe's ability to resist high temperatures up to 1090 degrees Celsius (1994 degrees Fahrenheit) during a fire.

S240P: Represents the safe's capability to resist high temperatures up to 1090 degrees Celsius (1994 degrees Fahrenheit) during a fire.

JIS Fire Resistance Level:

JIS S 1037: Fire resistance levels specified in the Japanese Industrial Standards, often including 60-minute, 90-minute, and 120-minute grades.

KS Fire Resistance Level:

KS G 4500: Fire resistance levels specified in the Korean Standards, covering different time periods during which the safe can withstand specific high-temperature levels.

These fire resistance levels are typically expressed in terms of time, indicating the duration during which the safe can maintain the internal temperature below a certain level in the event of a fire. Choosing the appropriate fire resistance level depends on the type of items you intend to store and specific requirements for fire resistance. When purchasing a fire safe, make sure to understand and consider the product's fire resistance level, making a wise choice based on your actual needs.

What are the leading safety brand with UL ratings?

Proway's UL listed fire safes are ideal for your home and business security. With strict UL ratings, this safe ensures a high level of security and performance. Its fire-resistant design protects important documents and valuables in the event of a fire, giving you extra peace of mind. Not only that, Proway’s fireproof safe is also waterproof, effectively resisting the impact of unexpected floods.

Proway specializes in the design and manufacturing of fireproof safes, ensuring product quality meets industry standards. Whether in home, office or commercial premises, this fireproof safe meets your high security requirements. Choosing Proway means choosing a professional, reliable and certified security solution to provide comprehensive protection for your valuables.

Copyright © 2021 Proway Industries co ltd. | All Rights Reserved